The 15-week trial of CIND’s advanced vision-based measurement system was conducted at WFS’ cargo terminal at Copenhagen Airport. Based on the successful assessment of the technology in live operational conditions, WFS intends to rollout the Dimensioner in Motion System at stations across its Europe, Middle East, Africa & Asia (EMEAA) region. The next five WFS airport stations to implement the system will be Amsterdam Schiphol, Arlanda Stockholm, Barcelona, Liège, and Paris Chales de Gaulle.

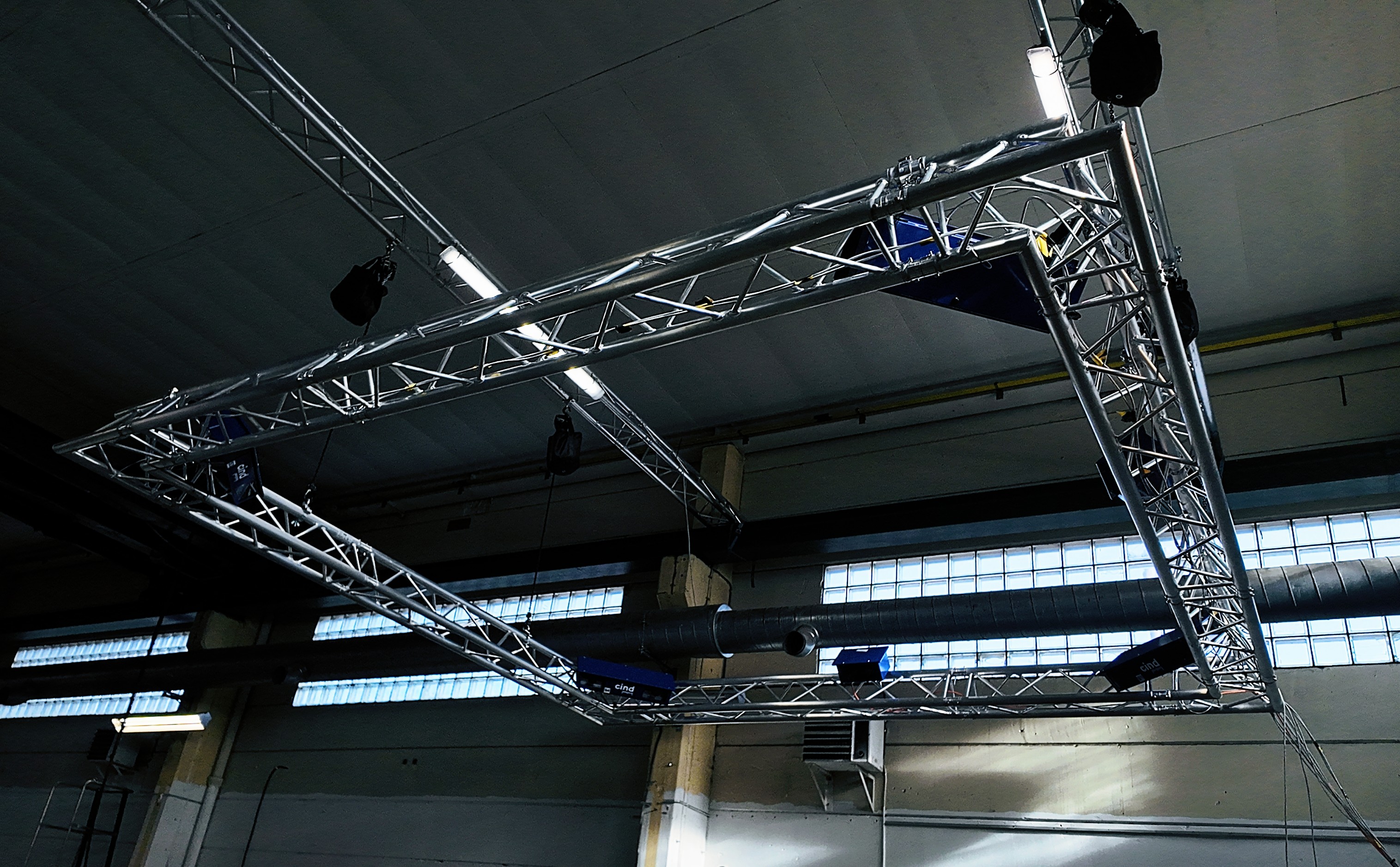

CIND’s Dimensioner in Motion uses stereo vision cameras, AI and algorithms to capture dimensions, and visual data automatically. It can measure and analyse standard and non-standard pallets in motion, whether transported by forklift, conveyor, or AGV (Automated Guided Vehicle). The system delivers precise measurements that comply with international standards with an accuracy of +-2cm and ensures the correct freight data is captured for accurate invoicing and aircraft space utilisation.

Volume calculations using the system are identified in under 2 seconds. In a high volume, high-speed cargo handling environment, WFS expects to process up to 500 pallets per hour using the CIND solution.

“The speed, accuracy and reliability of the Dimensioner in Motion System, versus traditional manual measurement, is clearly more efficient and will improve the overall cargo flow within our operations,” said Jimi Daniel Hansen, SVP Operational Excellence of WFS. “It gives us structured data reports on individual measurements and shipment level as well as photo evidence of measurements. It also conducts stackability analysis for our customers, based on pallet geometry, to determine if the pallet is suitable for stacking.”

The rollout of the Dimensioner in Motion is the latest digitisation collaboration between WFS and CIND, reinforcing a shared commitment to enhancing safety, transparency, and operational productivity through automated vision based cargo measurement technologies. It also supports WFS’ strategy to utilise new automation and digital technologies to transform cargo handling across a combined WFS/SATS global network spanning 225 stations in 27 countries, serving trade routes responsible for more than 50% of global air cargo volume.

“We have worked closely with WFS for many years, together pushing what will become the new standard. CIND Dimensioner in Motion is no exception, over the past months, we have jointly and at a rapid pace validated in real life operations new functionality designed to meet the demanding requirements of air cargo. WFS choosing us as their partner for automated data collection is another step forward, and together we continue to raise air cargo acceptance to the next level.” Marcus Schelin, CEO of CIND AB.

In 2024, WFS became the first air cargo handler to implement CIND’s ContourCheck 3D modelling software for enhanced data and transparency. For each flight prepared using ContourCheck, WFS’ airline customers receive a comprehensive digital report, complete with pictures, providing digital proof that each unit is fit to fly. As well as improving operational productivity, flight safety and compliance, the system is also being used at WFS cargo stations in Europe to improve build-up training.