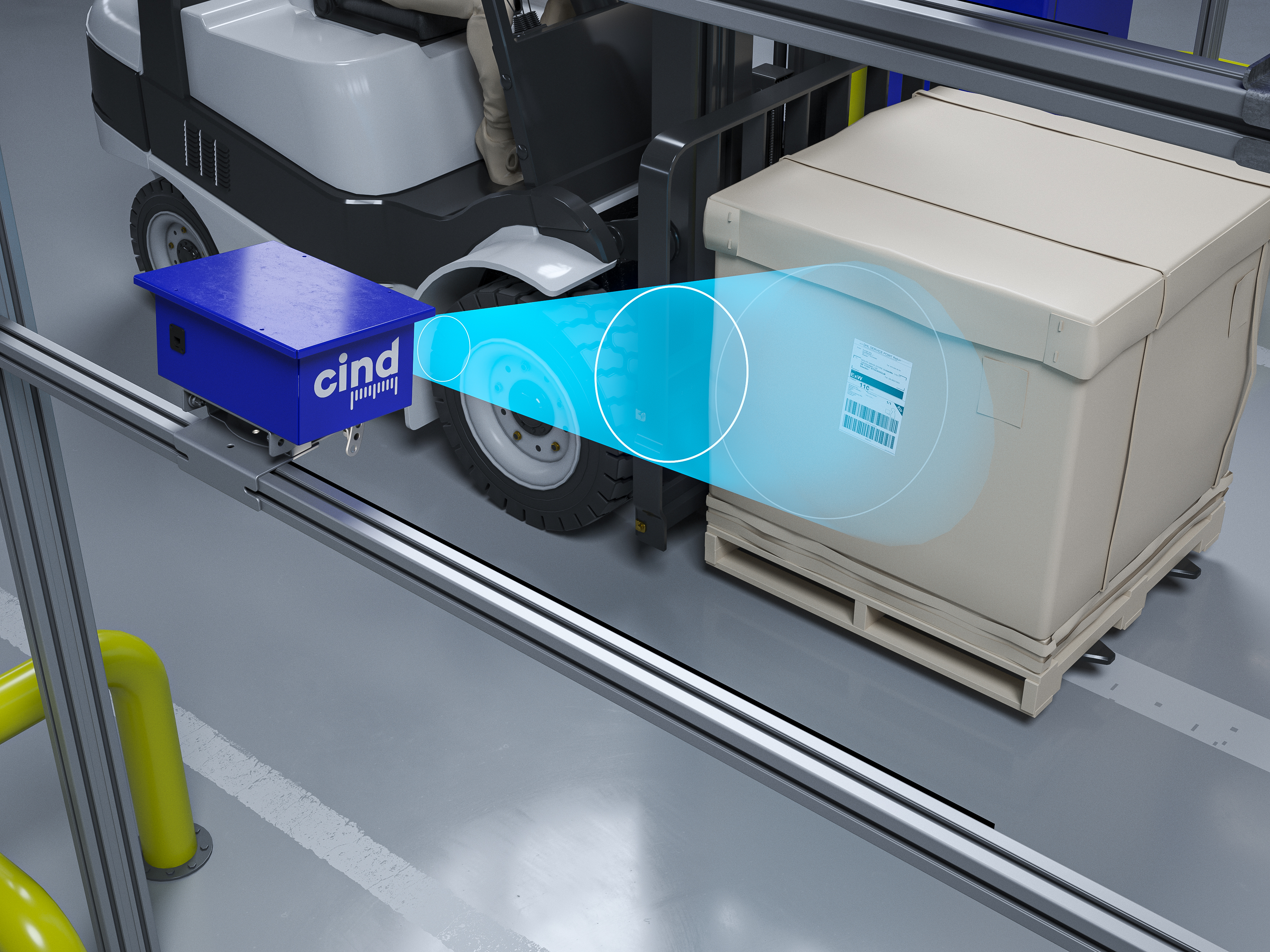

Automatic dimension measurement, weight, barcode reading, stackability testing, and analytics of palletized goods in motion. Developed together with leading logistics companies with the goal to measure dimensions automatically and effortless. Our innovative dimensioning systems help logistic companies around the world save time, money, and labor.

Gain complete control of your palletized goods

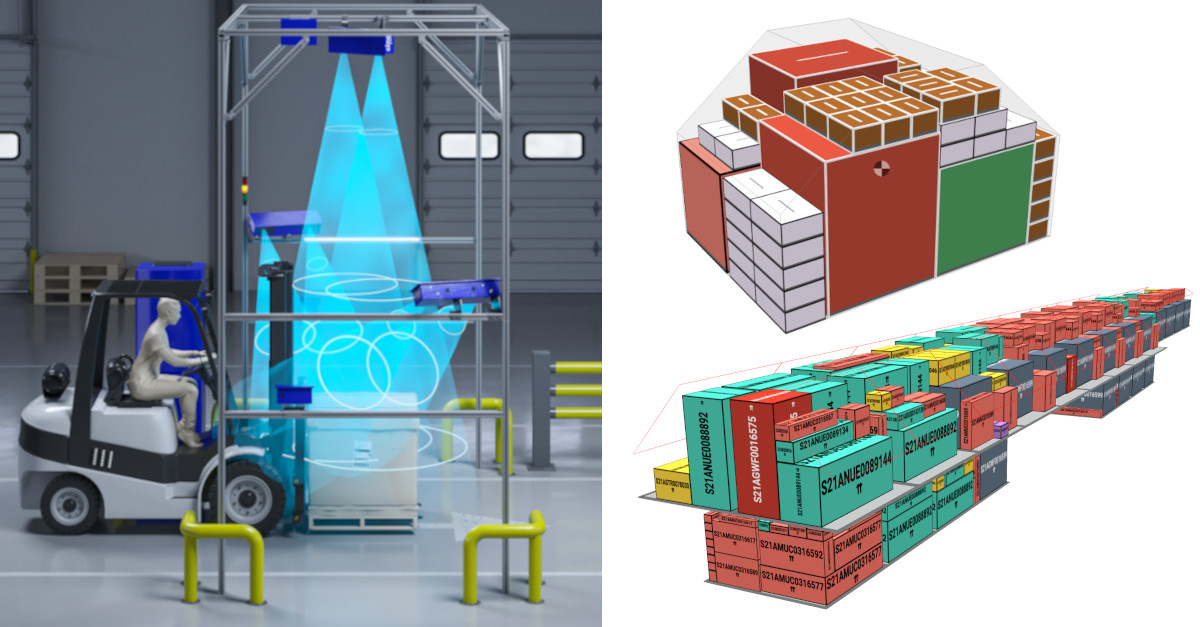

CIND Dimensioner automates the measurement and registration process of all your palletized goods. Innovative in-motion technology enables fast and efficient volumetric measurement regardless of whether the flow is based on forklifts, AGVs or conveyor belts. Barcode reading technology and stereovision cameras provide you with all the information you need to create an optimized workflow.

Features & benefits

MID/NTEP-certified

Rigorously tested and verified as “Legal for trade”.

Cost-efficient

Our subscription model ensures a short ROI while guaranteeing continuous service and updates.

Barcode reading

Labels are automatically identified, barcodes are scanned and assigned to each shipment.

Stackability check

The collected data is used to analyze stackability, so you can optimize your processes going forward.

Packaging material

The image processing technology is able to handle objects of all shapes and all materials, even black foil.

Images of all shipments

Every shipment is visually documented, which makes it easy to look back on if needed and can be a valuable asset in customer complaints.

Frequently asked questions

See our most common questions for our Dimensioner In-Motion to find out more about the system and performance.

Dimensioner In-Motion News

-

CIND x IAG CARGO - Pressrelease

IAG Cargo Takes Off with Automated Scanning at London Heathrow with Cind’s Dimensioner

• Cind AB has partnered with IAG Cargo to install an AI-powered camera solution that will calculate dimensions and provide data on freight movements in real-time

• The solution will lead to improved efficiency and a high-quality service for IAG Cargo customers

-

Data - the key to unlock cargo potential

The logistics industry is currently on an accelerating journey towards optimization and digitization.

Every day, vast quantities of cargo are transported around the world and we want to share why we believe it’s important to collect as much data as possible.

Since 3 years, logistics flows have been booming and companies need to adapt to a demand higher than ever. With our solutions this collection is fully automated and dynamic. -

CIND x Cargo-Planner.com - Strategic Partnership

[Jönköping & Malmö] – This partnership aims to set the standard for the logistics industry by integrating Cind's advanced data collection capabilities with Cargo-Planner's algorithms to perform load planning within seconds.

-

Five benefits of logistics automation

-

CIND is now a Logiconomi connection

We’re now part of Toyota Material Handling Europe Logiconomi connections.

Another step forward in our work to build stronger industry connections across the logistics industry.

Interested?

Contact us and learn more about how to eliminate time, costs, and errors from your freight operations!