How does dynamic 3D measurement work?

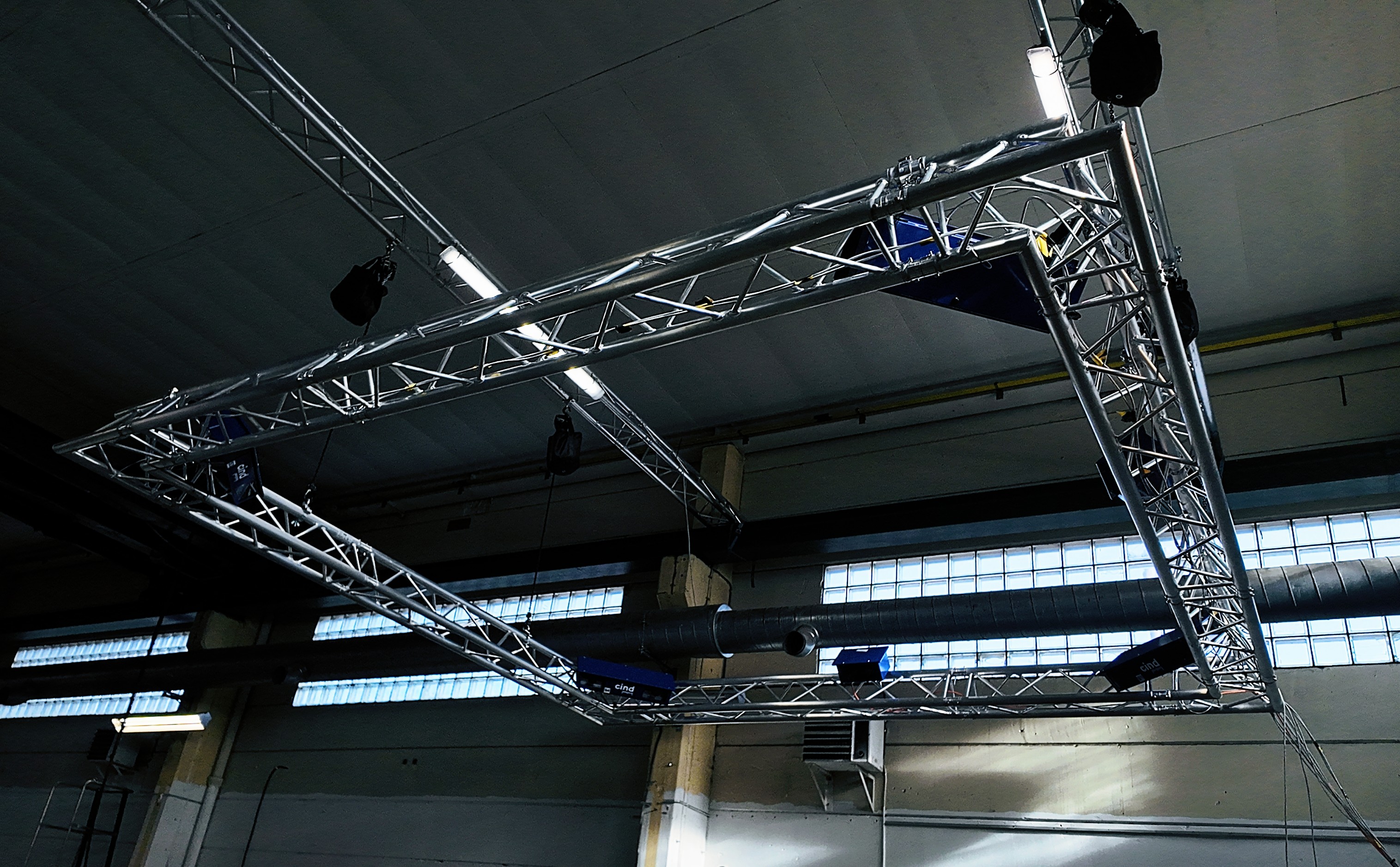

The first step of the 3D measurement process is that sensors scan a truck and its load. Regardless of whether the load consists of logs, wood chips or sawdust, Cind's patented software applies a unique set of algorithms that are able to distinguish between the raw materials and the truck. Thereafter, a 3D model of the load is generated, as well as 2D images that are simultaneously saved and included in the advanced processing of the data.

In less than a minute, the software is able to accurately calculate the volume and dimensions of the load. The system is also prepared to automatically detect species, oversized logs, contamination etc. through the use of artificial intelligence.

What makes dynamic 3D measurement unique is that, as the term implies, the software is able to capture and process data from a truck in motion. This feature saves a considerable amount of time and facilitates an enhanced flow in the transportation process.

Benefits of dynamic 3D dimensioning in the timber and forest industry

Reliability at all times

The technology makes it possible to perform uninterrupted transports and to accept deliveries around the clock, 7 days a week. The software is developed to deliver accurate data in challenging weather conditions such as snow, rain or strong sunlight.

Fully automatic measurement process

The high level of automation reduces labour costs and errors, while at the same time increasing the productivity.

Software-based and future-proofed

A software-based system can be upgraded with new functionality and the latest upgrades as soon as they are available, without the need for physical hardware to be exchanged.

Measurement capacity and efficiency

Companies in the timber and forest industry that handle large volumes in their business operations make more efficient use of their resources when waiting times are reduced.

*If you would like to know more about our patented intelligent 3D volume measurement systems and how they can be applied to your business, do not hesitate to get in contact with us at Cind.